Description

With a wear resistance that is orders of magnitude higher than any other E3D nozzle, ObXidian is really hard: several orders of magnitude harder than Nozzle X and any other generic hardened steel nozzle.

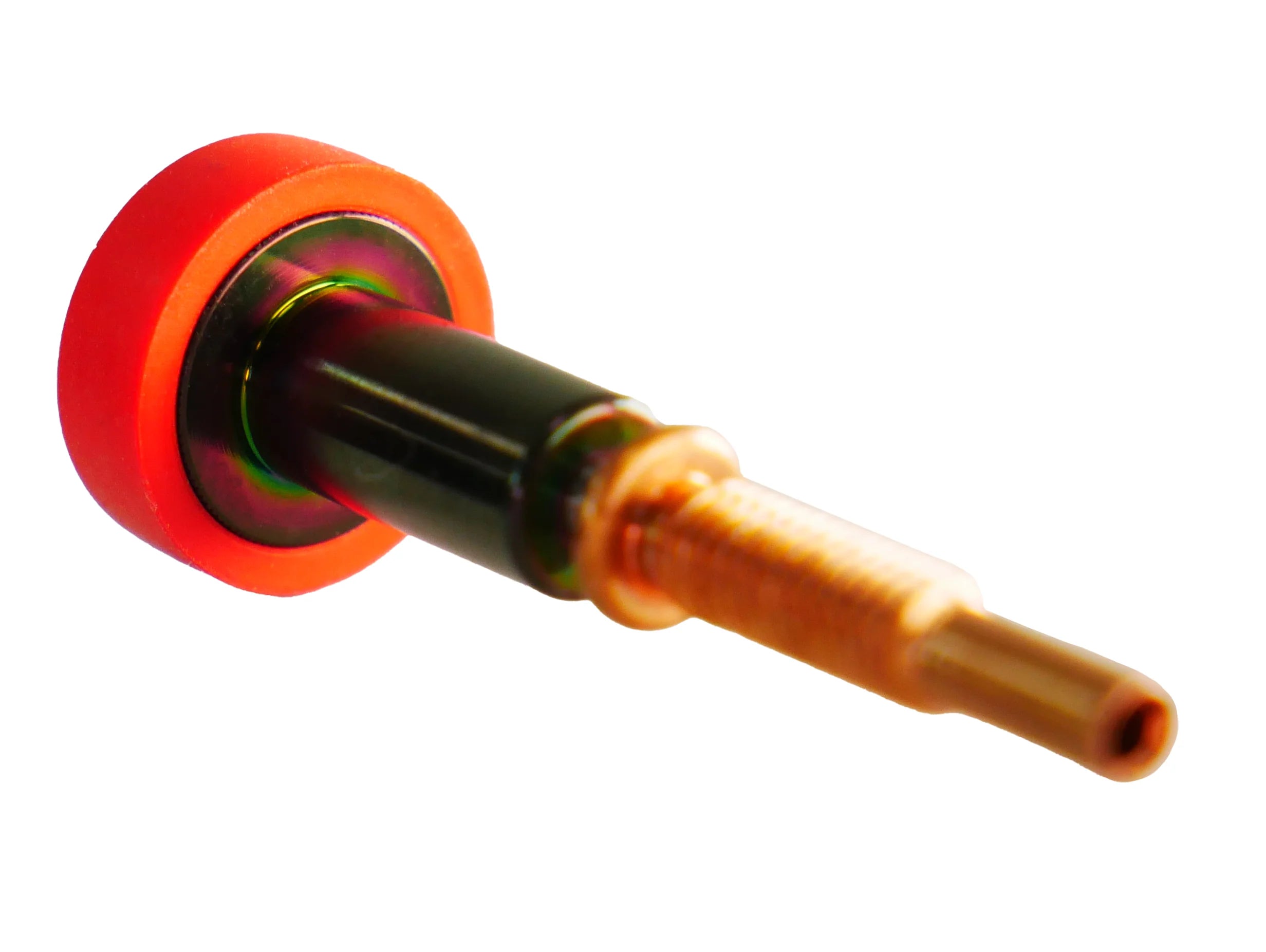

This is achieved by pairing a tool steel insert with our new E3DLC™ coating. This specially formulated coating also embeds non-stick properties into the Nozzle itself. Meaning considerably less plastic build-up around the Nozzle.

Experiment freely. With nozzle swapping this easy, you’re free to experiment with nozzle sizes you might not have used before. Set your 3D printer up for ultra-fine or ultra-thick extrusion widths in no time at all. Print large objects in less time, or tiny objects with high resolution.

Frustration-free. Each Revo Nozzle is a preassembled nozzle and heatbreak in one unit, so there’s no hazardous hot tightening and no chance of incorrect assembly. Say goodbye to frustrating HotEnd leaks and enjoy reliable 3D printing!

Rapid identification. Identify nozzle sizes at a glance thanks to a colour-coded silicone sock. Plus, each Revo Nozzle has its size engraved into it with easy-to-read numbers, so there are no confusing identification markers to learn!

An expanding range. We’re ready to make RapidChange Nozzles in any size. At launch, we’re introducing brass nozzles in 0.25mm, 0.4mm, 0.6mm and 0.8mm, with many more compatible nozzles to follow later. Wear-resistant and high flow variants are already on our roadmap and will follow over time.